| Module | Module Name | Links | Links | Blake's Links |

| PM | Plant Mantenance | tutorials point | Blake | |

| MM | Material Management | tutorials point Overview | Guru99 | Blake: 1-10 | 11-20 | 21-25 |

| SD | Sales and Distribution | tutorials point Tutorial | Guru99 | Blake |

| PP | Production Planning | tutorials point Tutorial | Guru99 | Blake | 1-7 |

| External Links | ||||

| NewLanguage.html | FICO Module: Blake's : Tutorials Point | |||

| 1 | Home | PP_Doc Tutorials Point | 11 | Material Req..ment Planning | PP_Doc Tutorials Point | 21 | Stock Overview | PP_Doc Tutorials Point | ||

| 2 | Introduction | PP_Doc Tutorials Point | 12 | MRP List | PP_Doc Tutorials Point | 22 | Goods Issue | PP_Doc Tutorials Point | ||

| 3 | Common Tables | PP_Doc Tutorials Point | 13 | Long Term Planning | PP_Doc Tutorials Point | 23 | Goods Issue Reversal | PP_Doc Tutorials Point | ||

| 4 | Organization Structure | PP_Doc Tutorials Point | 14 | Production Orders | PP_Doc Tutorials Point | 24 | Lean Manufacturing | PP_Doc Tutorials Point | ||

| 5 | Integration with Other Modules | PP_Doc Tutorials Point | 15 | Production Orders Change | PP_Doc Tutorials Point | 25 | Reports | PP_Doc Tutorials Point | ||

| 6 | Master Data | PP_Doc Tutorials Point | 16 | Production Orders Confirm... | PP_Doc Tutorials Point | 26 | Material Doc..ment List | PP_Doc Tutorials Point | ||

| 7 | Bill of Materials | PP_Doc Tutorials Point | 17 | Canceling Production Order | PP_Doc Tutorials Point | 27 | Stock of Multiple Mat... | PP_Doc Tutorials Point | ||

| 8 | Work Center | PP_Doc Tutorials Point | 18 | Capacity Planning | PP_Doc Tutorials Point | 28 | List in Bill of Material | PP_Doc Tutorials Point | ||

| 9 | Demand Management | PP_Doc Tutorials Point | 19 | Capacity Leveling | PP_Doc Tutorials Point | External Links | ||||

| 10 | Creating PIR | PP_Doc Tutorials Point | 20 | Goods Receipt | PP_Doc Tutorials Point | Create Plant | Tick Mark | |||

SAP Production Planning is one of the key modules in ERP and deals with planning processes, such as capacity planning, material planning, execution of production order, bill of material and goods movement. SAP PP module handles the master data required for Bill of Materials (BOMs) activity, work center and routing, and keeps it in a separate component.

SAP PP submodules vary as per industry type like discrete production, repetitive production, or production industries.

Discrete production is an industry where produce materials change with each lot and costs are calculated as per orders and lots.

In repetitive production, the product is not changed for a long period of time. Production takes place in total quantity and not in the form of individual lots.

For most of the industry types, above-mentioned planning and execution submodules are commonly used. Before the production execution, many steps are performed as a part of the planning process −

Material Requirement Planning (MRP) run (More details later in this tutorial).

Bill of material and routing master data is entered in a planned order automatically with MRP run.

Planning quantities are maintained in the system.

Following are the key steps in executing a production order. It starts with a planned order and ends with goods receipt against a Production order.

The first step is to convert a planned order to production order. When you create a production order, type is defined in SAP PP system.

To start the production process, it is necessary to issue production order. Till a production order is released, execution of the production process cannot start.

To execute the production order, goods need to be issued. Once goods are issued, the document number can be updated in the system.

All the sub processes are executed in accordance with the required operations to confirm the production as per the production order.

Once the execution of production order is complete, goods produced w.r.t production order are received and placed in the storage area.

In this chapter, we will discuss some of the important tables in SAP PP.

| Table | Description |

|---|---|

| MDKP | Document Header data |

| MDTB | Table Structure |

| MDVM | Planning File Details |

| MDFD | MRP Date details |

| S094 | Stock Analysis |

| Table | Description |

|---|---|

| PBED | Independent Requirements Data |

| PBIM | Independent Requirements by Material |

| Table | Description |

|---|---|

| PLAF | Planned Order Details |

| Table | Description |

|---|---|

| S025 | Run Schedule Quantities |

| S026 | Material Usage |

| S028 | Reporting Point Statistics |

| SAFK | RS Header Master Data |

There are various tables in SAP PP system for BOM, routing, discrete production, material allocation, goods receipts, etc.

| Table | Description |

|---|---|

| MAST | Material BOM |

| STKO | BOM Header |

| STOP | BOM Positions |

| PLKO | Routing Group Header |

| PLSO | Routing Group Sequence |

| PLPO | Routing Group Operations |

| AFKO | Production Order Header |

| AFPO | Production Order Position |

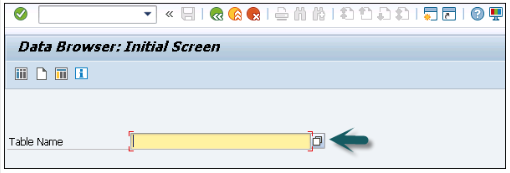

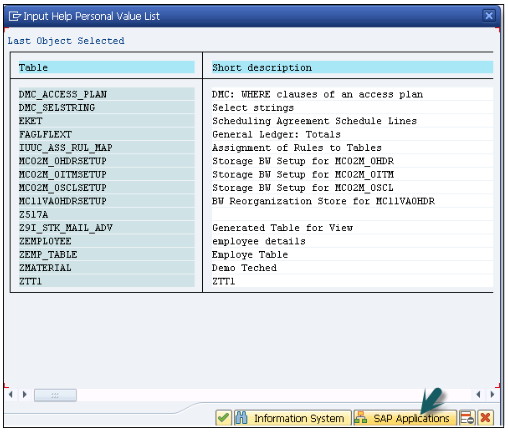

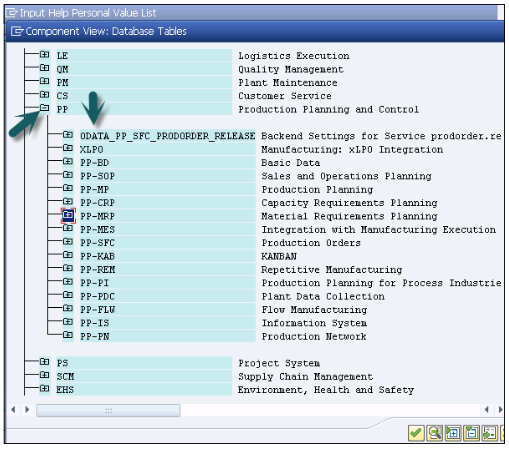

Step 1 − In ERP system, use T-Code: SE16.

Step 2 − Go to SAP Applications.

Step 1 − Click the ‘+’ sign and you can see the list of all tables in ERP as shown in the following screenshot.

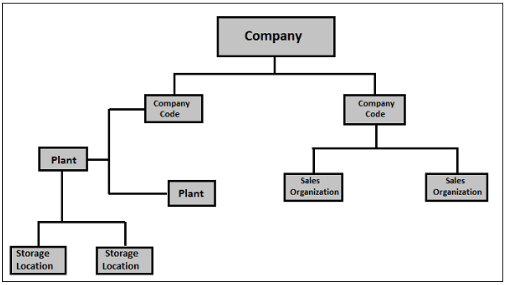

In SAP PP module, the organization structure defines the location of manufacturing plants and storage locations within the plant.

At the top of the structure, you have the company and the company code and then each company code contains different plant and storage locations.

Following diagram represents a common organization structure in live SAP Production Planning environment.

All the planning activities are performed at the plant level.

Production master data in Production Planning is created at the plant level.

Production confirmation process and the movement of goods occur at the plant and storage level.

To perform Production Planning and Control activities, SAP PP is closely integrated with other SAP ERP modules: SAP Sales and Distribution (SD), SAP Material Management (MM), Quality Management, Finance Accounting, and Project System.

You can find a list of the following activities from Production Planning that are related to other SAP modules and integration with other modules.

This involves movement of goods, auto goods receipt.

It includes creating a reservation for Production Order/Planning.

Raising purchase orders with MRP Run.

Quotations and Vendor selection.

This is used to check the availability of material for production order.

To perform MRP Run, Requirement Types.

Bill of Material components and operation.

Updating price in material master data.

Defining activity type in the cost center.

Assigning activity type to work center.

Cost Estimation.

Production cost controlling

Posting accounting activities related to goods movement, material request, etc.

Assigning planning activities to WBS in the Project.

Running Material requirement planning at Project level (MD51). The procured material attached to WBS are reserved as project stock against the particular project.

The component attached to the network are planned at the plant level and are reserved as plant stock.

Inspection Type 03 for discrete and repetitive manufacturing.

Inspection Type 04 for both discrete and repetitive manufacturing.

Following are the types of master data that exists in PP −

Bill of materials master data is related to material requirement planning and provides the list of components to produce the product.

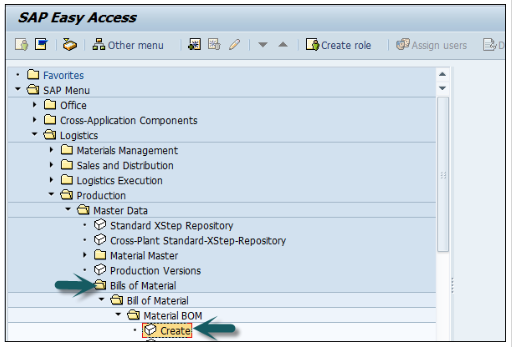

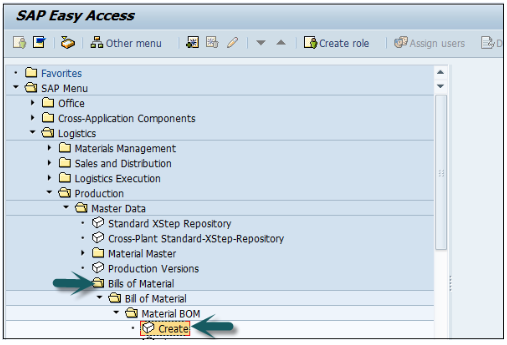

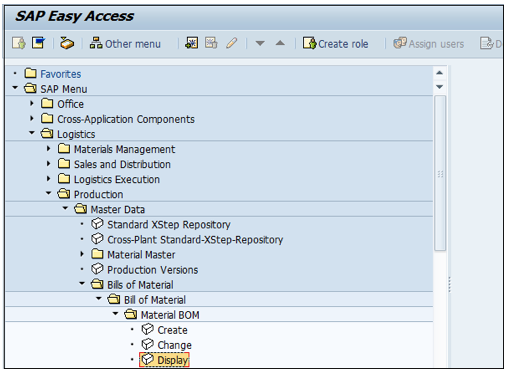

For Bills of Material master, use T-Code: CS01 or go to Logistics → Production → Master Data → Bills of Material → Bills of Material → Material BOM → Create

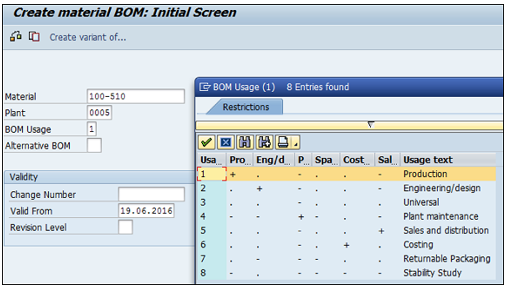

Select the following details − as displayed in the screen below

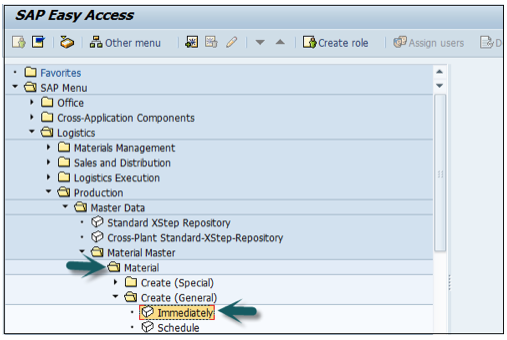

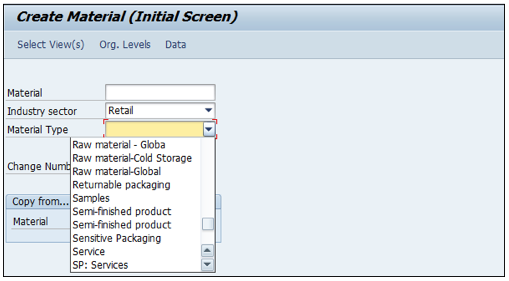

For Material master data, use T-code: MM01 or go to Logistics → Production → Master Data → Material Master → Material → Create (General) → immediately

Enter the following details −

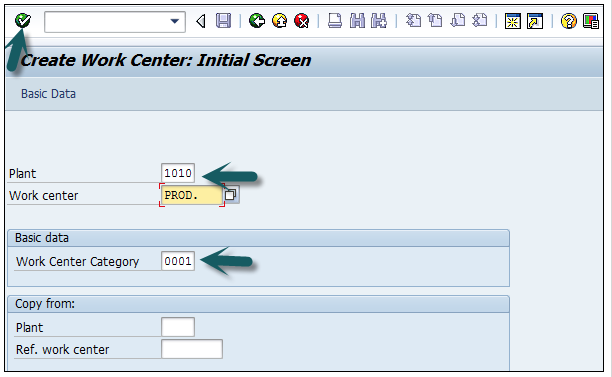

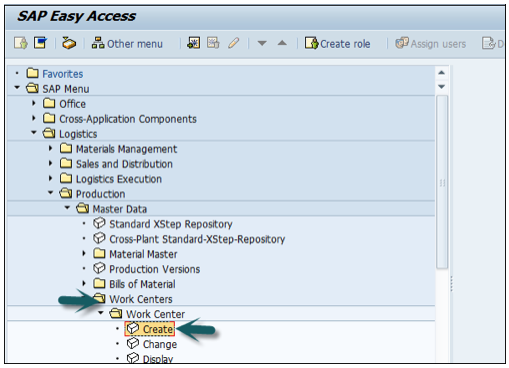

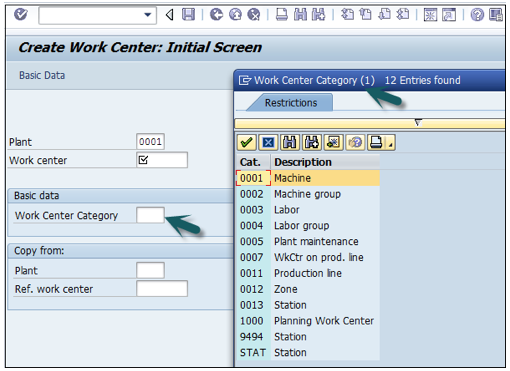

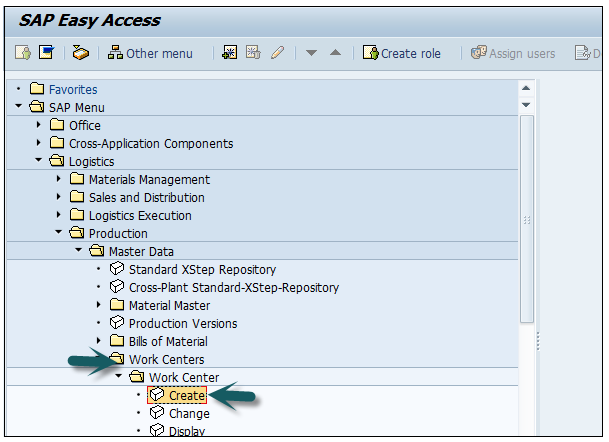

For work center, use T-code: CR01 or go to Logistics → Production → Master Data → Work Centers → Work Center → Create

Enter the following details −

Select Work Center Category and click the tick mark.

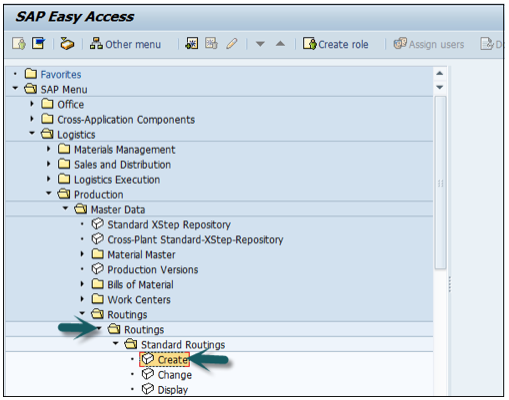

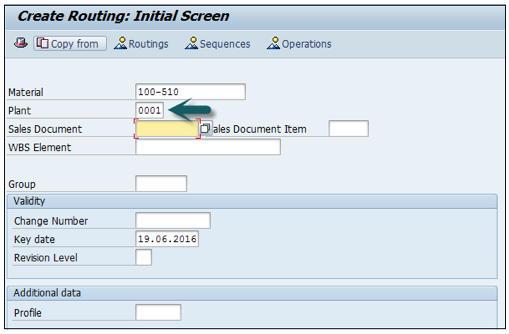

For Routing Master data, use T-Code: CA01 or go to Logistics → Production → Master Data → Routings → Routing → Standard Routing → Create

Enter the following details −

Click the tick mark.

Bill of Materials master data is related to material requirement planning and provides the list of components to produce the product.

You can create single level or multiple level Bill of Materials.

BOM type depends on the size, validity dates, and production method.

You can create up to 99 Bill of Materials as per the material type.

You can use material Bill of material for the material available in PP module and equipment Bill of Material is used in Plant Maintenance module.

As mentioned you can create super BOM for different variants of a product.

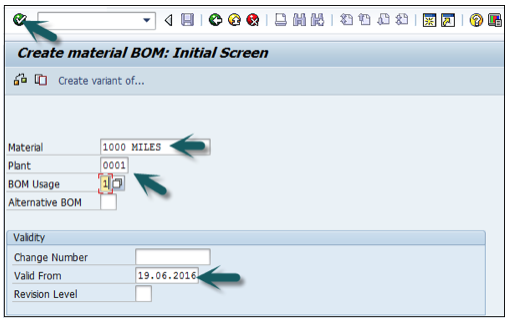

Use T-Code: CS01 or go to Logistics → Production → Master Data → Bills of Material → Bill of Material → Material BOM → Create

Select the following details −

By default, it takes the current date as Valid from. You can select the date as per your requirement.

Click the tick mark at the top of the screen.

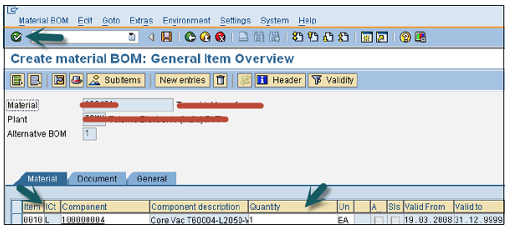

In the next window, enter Item category ‘L’. L shows the stock item and N shows nonstock item.

Enter the following details −

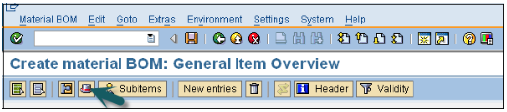

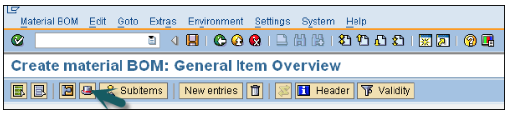

Few of the fields it will automatically fill up. Click the tick mark at the top of the screen as shown in the following screenshot.

To see Bill of Material header −

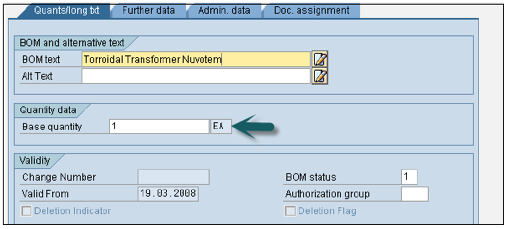

Enter the base quantity of the parent material. If this is 1 EA (each), then the component quantity will describe how much is needed to produce 1 item.

To save BOM, click Save the new BOM, after check.

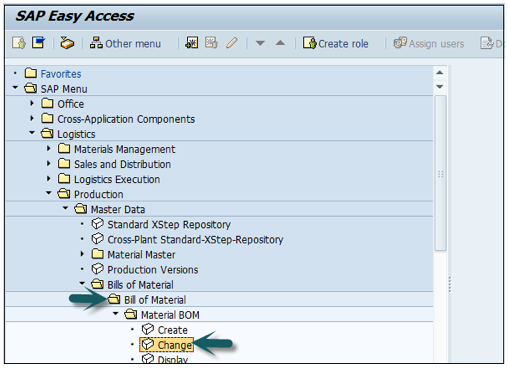

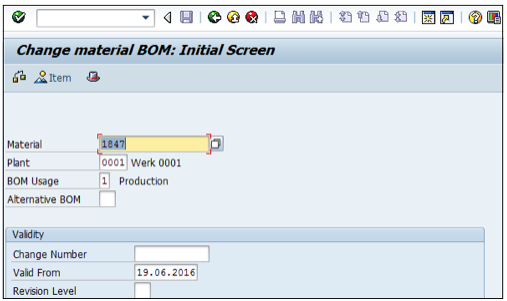

To change Bill of Material, use T-code: CS02 or go to Logistics → Production → Master Data → Bills of Material → Bill of Material→ Material BOM → Change

Enter the following details −

Click the tick mark on the top of the screen.

You can edit the item category, component or quantity. Click the Save icon at the top of the screen to save the changes to BOM.

Use -Code: CS03 or go to Logistics → Production → Master Data → Bills of Material → Bill of Material → Material BOM → Display

Enter the following details −

Click the tick mark on the top of the screen. To see BOM Header data, click the Header icon.

You can display BOM header and check the base quantity of the product.

There are two types of BOMs −

When a BOM is created for a material, it is known as a material BOM in SAP. Material BOMs are mainly used to represent the structure of products manufactured within your company.

Use T-code: CR01 or go to Logistics → Production → Master Data → Work Centers → Work Center → Create

Enter the following details −

Select the Work Center Category and click the tick mark.